1.What is a UV printer?

A UV printer is a high-precision, high-speed, high-tech digital color printing machine that does not require plates and is not limited by materials, with selectable precision. It is different from traditional printers; the UV printer is named for its use of UV ink. The UV printer ejects UV ink through the print head, and then the ink is cured on the printing material by UV light irradiation, which greatly facilitates production or sampling. Its personalized production mode also brings unprecedented convenience to the processing and advertising industries.

2.Classification of UV printers

The classification of UV printers The commonly seen UV printers on the market are mainly divided into three categories: UV flatbed printers, UV roll-to-roll printers, and UV belt printers that can achieve multiple functions with one machine.

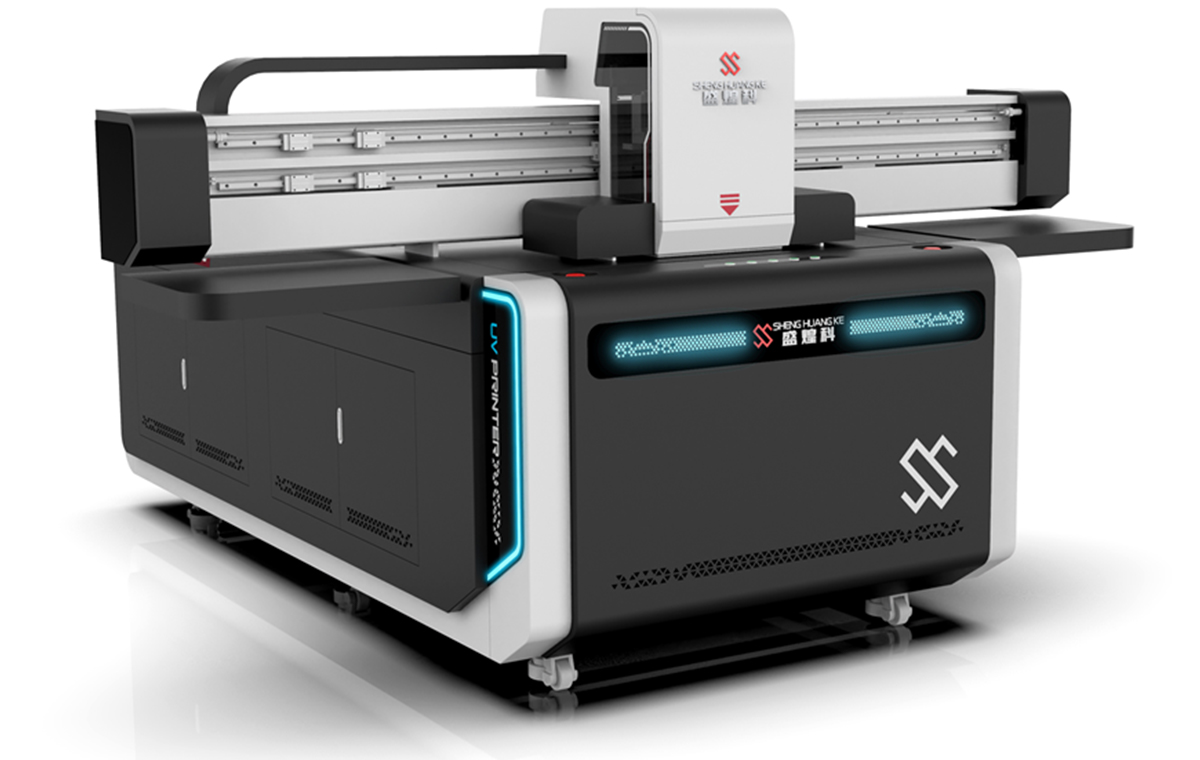

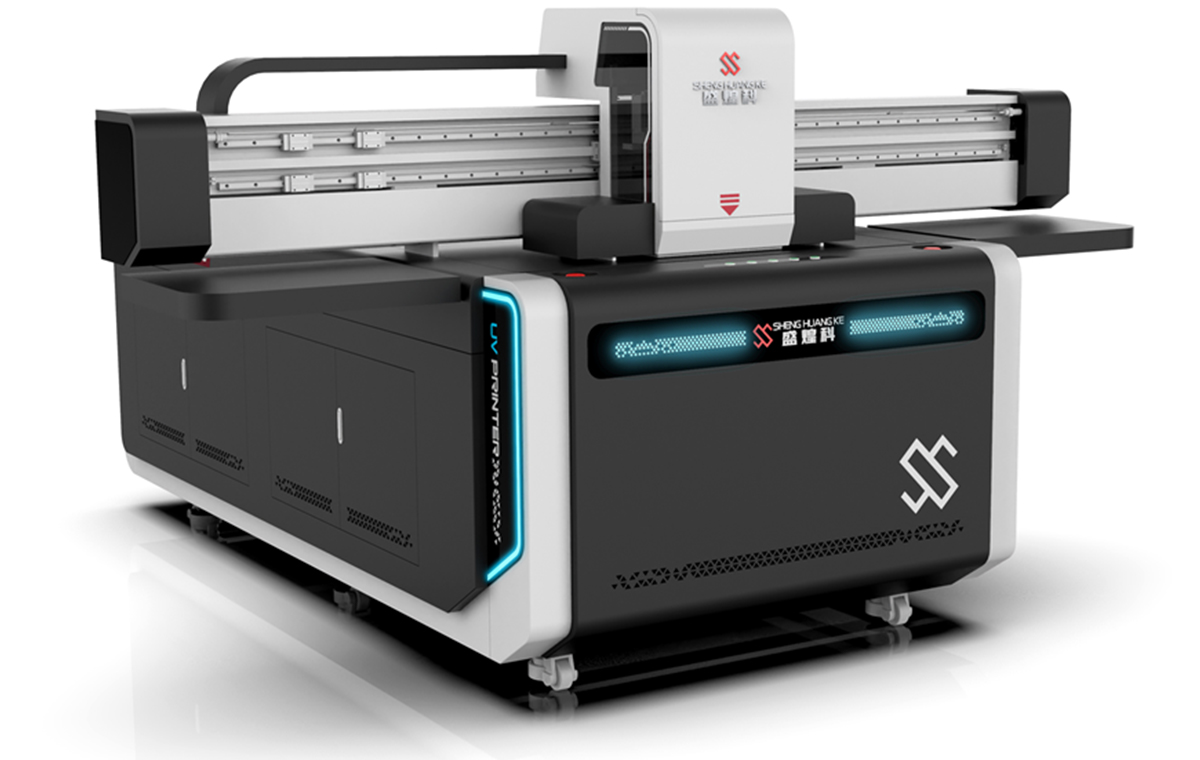

① UV Flatbed Printer: The flatbed printer is the most common type of UV printer, also known as a universal printer. It operates by moving the print head along the X and Y axes to spray-paint, and uses high-power suction to fix the product onto the platform, completing the printing process through the movement of the X and Y axes. It can print on 95% of flat materials available on the market. Flatbed printers can print on both roll materials and sheet materials. Roll materials include lightbox cloth, soft media, canvas bags, wall cloth, curtains, carpets, etc.; sheet materials include PVC, acrylic, KT boards, wood boards, wall panels, etc. The equipment is widely used, covering industries such as advertising, luggage leather goods, home decoration, packaging, and more.

Advantages: Precise timing, allowing printing anywhere within the print size range. The print pattern can be repeated multiple times to create a relief effect.

Disadvantages: The print size is fixed according to the size of the machine and cannot exceed the platform’s limits. Common print platform sizes include 1.3x2.5, 0.9x0.6, 1.0x1.6,A3, etc.

② UV Roll-to-Roll Printer: Its working principle is similar to that of the UV flatbed printer, but it is more suitable for printing on soft materials, such as lightbox cloth, oil painting canvas, knife-scratched cloth, transparent soft film, leather, etc.

Advantages: It can print materials of unlimited length.

Disadvantages: The positioning is relatively imprecise, and the range of printable materials is somewhat limited.

③UV Conveyor Belt Machine: Also known as a UV flatbed roll-to-roll integrated machine, it possesses the common characteristics of both roll material machines and flatbed printers, and can switch modes freely, achieving multiple uses in one machine. It operates by moving the print head in the X-axis direction for printing. The print head cannot move back and forth; instead, the conveyor belt moves the material in the forward and backward directions. Theoretically, the conveyor belt machine can print materials of unlimited length. The platform of the UV conveyor belt machine is independent, and when customers need to use the platform, they can simply install it for use.

Advantages: Versatile for both flat and roll printing, capable of printing a variety of patterns.

Disadvantages: The assembly and disassembly can be cumbersome and must be determined based on specific circumstances.

3.Classification of UV Printer Inks:

Commonly used UV printer inks on the market are divided into three types: hard, soft, and neutral. For flat, hard materials printed by UV flatbed printers, such as acrylic, glass, metal plates, etc., hard or neutral inks are commonly used. For soft materials printed by UV roll printers, such as lightbox soft film, lightbox cloth, wall cloth wallpaper, etc., soft inks are commonly used.

This is because using hard ink on soft materials can cause tearing when the material is stretched; whereas using soft ink on flat materials can lead to reduced adhesion strength.

4.Conclusion:

Today, the traditional printing industry continues to innovate with the advancement of technology, and UV inkjet technology is a prime example of this on a global scale. UV printers have become an essential tool across various industries, as they are almost universally applicable to all flat materials. They are widely used in the advertising industry, building materials and decoration industry, arts and crafts industry, and digital products industry, with a very broad development prospect.